Investing in a CNC machine can yield substantial benefits for businesses. This article examines the financial advantages, precision, and productivity gains associated with CNC technology, helping you decide if it’s a smart investment for your manufacturing operations.

CNC Machines

What is a CNC Machine?

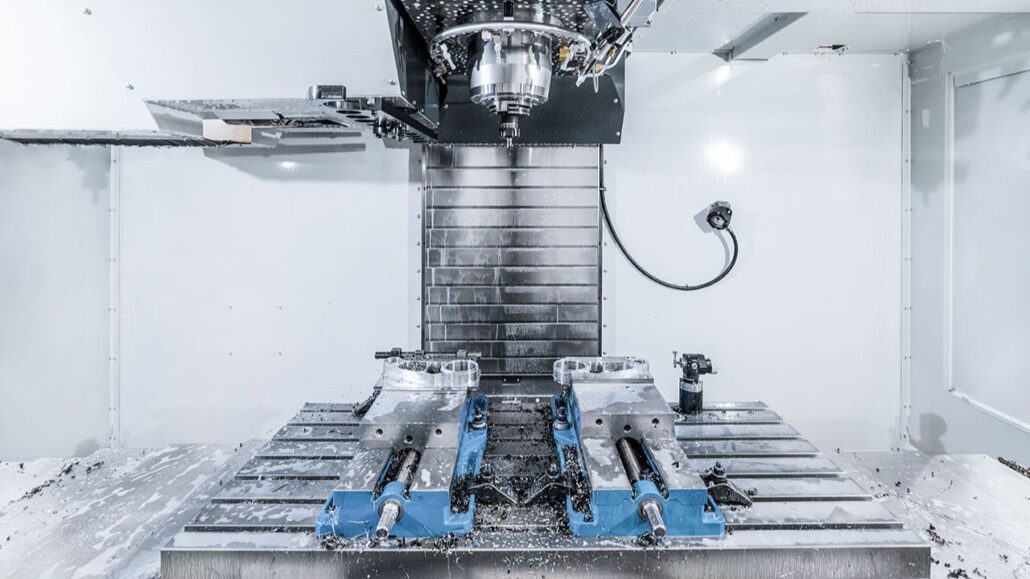

A CNC machine, short for Computer Numerical Control machine, is an automated manufacturing tool that utilizes computer programming to control its various mechanical components. These machines are used in a wide range of industries, including astrionics, automotive, woodworking, and metal fabrication.

How Does a CNC Machine Work?

CNC machines work by interpreting design specifications from computer-aided design (CAD) files. The machine then precisely moves and controls tools to shape and cut materials into the desired shapes and dimensions. This automated process ensures high accuracy and repeatability.

Advantages of Investing in CNC Machines

Enhanced Precision and Accuracy

One of the most significant advantages of using CNC machines is their unmatched precision. These machines can perform intricate tasks with incredible accuracy, reducing the margin of error to almost zero. This level of precision is crucial in industries where even a minor error can result in costly defects.

Increased Productivity

CNC Machine Investment can operate 24/7 without breaks, leading to increased productivity. They can complete tasks faster than manual labor, which not only saves time but also reduces labor costs. This efficiency boost can significantly impact your bottom line.

Versatility

CNC machines can be programmed to work with various materials, from metals to plastics to wood. This versatility makes them suitable for a wide range of industries and applications, providing flexibility to adapt to changing market demands.

Consistency in Production

Human workers may experience fatigue or inconsistency in their work, but CNC machines maintain a consistent level of quality and precision throughout the production process. This consistency is vital for maintaining product quality and reputation.

Considerations Before Investing in CNC Machines

Initial Investment Costs

While CNC machines offer long-term benefits, they require a substantial initial investment. Businesses must carefully evaluate their budget and financial resources before making this commitment.

Skilled Operators

Operating CNC machines requires trained professionals who can create and modify the necessary computer programs. Investing in employee training is essential to harness the full potential of CNC technology.

Maintenance and Upkeep

CNC machines require regular preservation to ensure optimal performance. Businesses should be prepared for ongoing maintenance costs and downtime.

CNC Machine Investment Pros and Cons

The advantages and disadvantages of investing in CNC machines for your business. Discover how these automated tools can impact productivity and profitability.

ROI of CNC Machines in Manufacturing

Learn about the Return on Investment (ROI) potential of CNC machines in the manufacturing industry. Uncover the financial benefits and long-term gains these precision tools can offer.

Maximizing Profits with CNC Machine Investments

Discover strategies and tips for maximizing your profits through wise investments in CNC machines. Explore how these machines can enhance efficiency and boost your bottom line.

Choosing the Right CNC Machine for Your Business

Find guidance on selecting the perfect CNC machine for your specific business needs. Understand the various types and features available to make an informed decision.

What are The Benefits of CNC machines?

Certainly! CNC machines open up opportunities in various industries, from manufacturing to custom woodworking. The key lies in finding your niche and delivering quality products or services.

How Profitable Is The CNC Machine Business?

Yes, they can be. The profitability depends on factors like market demand, efficiency in production, and your ability to manage costs.

How Durable Are CNC Machines?

Generally, yes. CNC machines are an investment, and their value can be maintained if properly maintained and upgraded over time.

Is CNC A Good Investment?

Investing in CNC can be smart if you carefully consider various factors. The initial investment is significant, but a demand for precision machining in your market can lead to a profitable venture. Assess the industry trends, potential competition, and your ability to provide quality services. Stay updated on technological advancements, as this can impact the longevity of your investment. A CNC machine can be a valuable asset for your business in the right circumstances

Is There a Future in CNC?

Absolutely CNC Machine a Good Investment. With technological advancements, the demand for precision machining is likely to grow. Staying updated with industry trends and continuously improving your skills can secure your place in the future.

Business Plan For CNC Machine Shop

A solid business plan should outline your target market, competition analysis, pricing strategy, marketing approach, and financial projections. It’s your roadmap to success.

Start-up Costs for CNC Machine Shops

The cost can vary widely, depending on the type of CNC machines, space, and tools required. Budgeting for equipment, software, maintenance, and marketing is essential.

The Risks of CNC Machine

Risks include initial capital investment, market fluctuations, and technological advancements that may render your equipment outdated.

What are the 3 Disadvantages of a CNC Machine?

- Initial Cost: CNC machines can be expensive to purchase and set up.

- Skill Requirement: Skilled operators are necessary for optimal performance.

- Maintenance: Regular maintenance is crucial, and unexpected breakdowns can disrupt production.

How Long Does a CNC Last?

With proper maintenance, CNC machines can last for many years. Upgrades and technology advancements may influence the lifespan.

What Is The Biggest Disadvantage Of Using CNC?

The biggest disadvantage could be the initial setup cost. It’s a significant investment that might be daunting for some entrepreneurs.

How Much Money Can You Make With a CNC Machine?

The earning potential depends on the market, your services, and your efficiency. It’s not uncommon for successful CNC machine shops to generate substantial revenue.

Financial Benefits of CNC Machine Ownership

Delve into the financial advantages of owning CNC machines. Learn how these machines can reduce labor costs, minimize waste, and improve your overall financial health.

Is CNC Machining Worth the Cost?

Evaluate whether the cost of CNC machining aligns with your business goals. Consider factors like precision, speed, and scalability to determine if it’s a worthwhile investment.

CNC Machine vs. Manual Labor

Compare the costs and benefits of using CNC machines versus manual labor in your manufacturing processes. Analyze how automation can impact your business’s financial outlook.

Conclusion

CNC Machine Investment can be a tremendous asset for businesses seeking to improve precision, productivity, and product quality.

While the initial investment and operational considerations may seem daunting, the long-term benefits often outweigh the challenges.

However, it’s essential to conduct a thorough cost-benefit analysis and invest in training and maintenance to maximize the advantages of CNC technology.

FAQ

Are CNC Machines Suitable for Small Businesses?

Yes, CNC machines can benefit small businesses, especially those involved in custom manufacturing and precision work. However, the initial investment should be carefully considered.

Can CNC Machines Work with Different Materials?

Absolutely! CNC machines are versatile and can work with various materials, including metals, plastics, and wood.

What Industries Commonly Use CNC Machines?

CNC machines are prevalent in industries such as aerospace, automotive, medical device manufacturing, and woodworking.

How Long does it take to Train an Operator to use CNC Machines?

The duration of training can vary, but it typically takes several months to become proficient in CNC programming and operation.

What Maintenance is Required for CNC Machines?

Routine maintenance includes cleaning, lubricating, and calibrating the machine. Additionally, software updates may be necessary to ensure optimal performance.